What conditions need to be considered when designing the lens of the LED injection module

Time:2020-09-03 来源:Dongguan Lianlong Optoelectronic Technology Co.Ltd

In the LED injection module, the lamp beads need to be equipped with a suitable lens to make the canvas achieve a wonderful effect, so when purchasing the lens of the LED injection module, we need to consider whether the lens manufacturer has the following basic conditions.

1. First consider what light source to use. The light source of different brands of LED injection modules will have different chip structure, packaging methods, light characteristics, etc., so that the same lens will be different when different specifications of brand LED light sources are used; therefore, the design is required The reader must be proficient in the performance parameters and specifications of the mainstream brand light sources, and develop the products that determine the light source in order to achieve the actual needs. This requires designers to have certain design experience with mainstream brand light sources.

2. The lens of the LED injection module uses mainstream optical design software and mechanical modeling software. At present, the main design software includes: CodeV, ZEMAX, TracePro, ASAP, LighTools, etc.; mechanical modeling software includes: Pro/E, UG, SOLIDWORKS, etc. These softwares are widely used, convenient for communication and modification, and can be used for optical simulation and continuous optimization to obtain corresponding optical lenses.

3. The lens of the LED injection module is a precision accessory in the optical field, so the accuracy of the mold is extremely high, especially the processing accuracy of the lens optical curved surface must reach 0.1μm. Generally, mold processing equipment with low accuracy cannot achieve such a high level of accuracy. For this, lens manufacturers must have the following high-precision mold processing equipment: ultra-precision processing machines (generally, the processing machines in Germany and Japan have the highest precision), CNC comprehensive processing machines, precision grinders, precision milling machines, drilling machines, CNC precision spark machines, Surface profiler, interferometer, etc.

4. The most precise part of the lens for manufacturing LED injection modules is the optical mold core. The preferred material should be a special mold core steel, such as Swedish S136 mirror steel, which is heat-treated to 55° to complete the rough embryo and nickel-plated on the rough embryo After processing, the surface is processed by an ultra-precision processing machine.

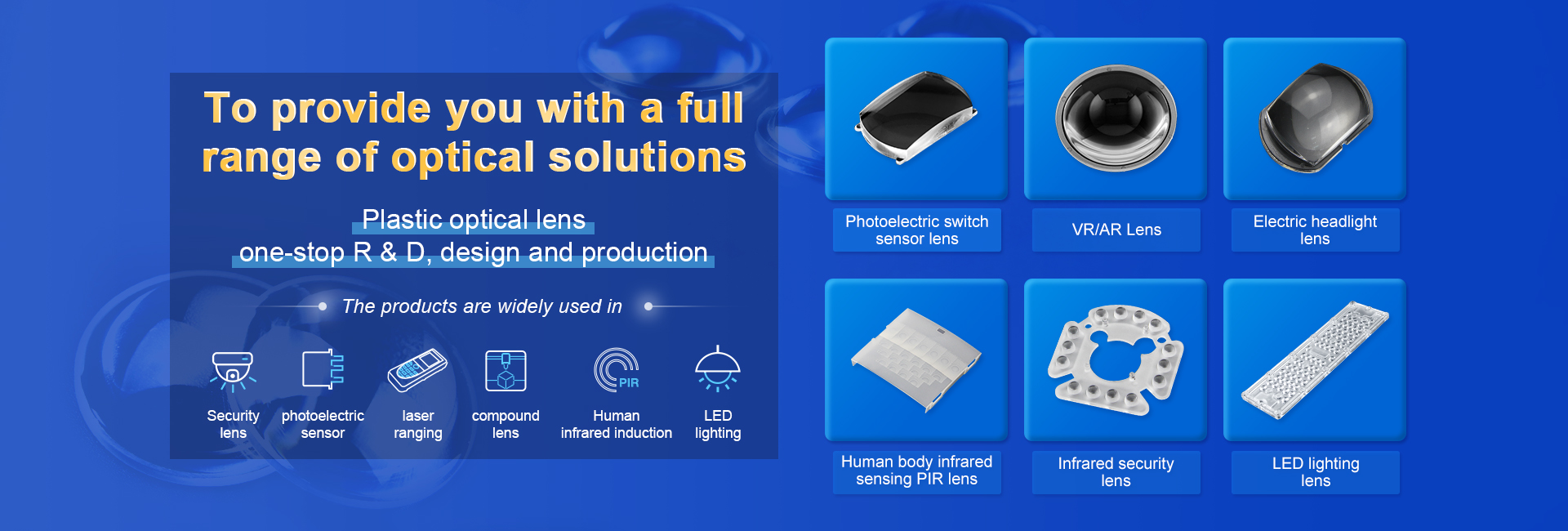

The above is the introduction of the lens design of the LED injection module. If you need more detailed information about the lens design of the LED injection module, please consult Dongguan Lianlong Optoelectronics Technology Co., Ltd., Dongguan Lianlong Optoelectronics Technology Co., Ltd. Lianlong Optoelectronics focuses on plastic optics Lens, optical lens R&D and customization strength manufacturer, we are a customized strength manufacturer integrating plastic optical lens and optical lens R&D, production and sales. The company uses optical-grade PMMA raw materials and optical-grade PC raw materials for production. Products are widely used in LED lighting/special lighting/electronic testing equipment/artificial intelligence AR/VR and other fields. Lianlong Optoelectronics strictly controls the selection of materials, and all staff strictly implement the ISO19001 quality system to provide customers with high-quality products and services.